Leading Tips for Effective Commercial Refrigeration Repair in Toronto

Leading Tips for Effective Commercial Refrigeration Repair in Toronto

Blog Article

Fixing Commercial Refrigeration Repair Work: Techniques for Quick and Effective Fixes

Understanding the typical issues that afflict business refrigeration systems and having a toolkit of diagnostic strategies at your disposal can make all the difference in quickly recognizing and fixing troubles. As we browse through the complexities of repairing industrial refrigeration repair work, we will certainly reveal the vital techniques for solving issues effectively, making sure that organizations can keep optimum cooling performance and reduce downtime.

Usual Commercial Refrigeration Issues

Commercial refrigeration systems frequently encounter a variety of operational problems that can disrupt their performance and efficiency. One widespread concern is incorrect temperature level control, which can bring about food perishing and waste otherwise promptly dealt with. This issue might come from problems with the thermostat, evaporator follower, or condenser coils, calling for detailed inspection to pinpoint the origin. Another usual issue is insufficient air flow, commonly brought on by clogs in the vents or a malfunctioning follower. Poor air movement can cause temperature level variances within the refrigerator or freezer, affecting the high quality and safety of saved items.

Furthermore, cooling agent leakages position a significant worry as they not only affect the cooling capability of the system but likewise add to ecological harm. Routine cleansing and upkeep can assist avoid this problem and extend the life expectancy of the refrigeration system.

Diagnostic Tools and Techniques

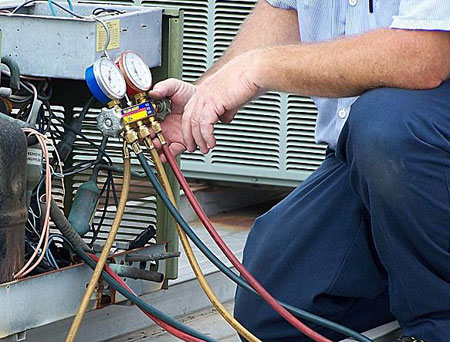

Efficient troubleshooting of industrial refrigeration systems relies heavily on making use of specialized diagnostic tools and techniques to recognize and fix underlying problems successfully - commercial refrigeration repair. In addition, leakage discovery tools like electronic leakage detectors or ultraviolet dye sets are important for finding refrigerant leaks that can lead to system ineffectiveness.

Strategies such as pressure testing utilizing manifold gauges can figure out if the system has the proper cooling agent charge and recognize any kind of leaks. Aesthetic inspections of parts for indications of wear, ice, or corrosion buildup are also essential in diagnosing concerns. Additionally, information loggers can be employed to check system performance in time and discover trends that may show reoccuring troubles. By integrating these diagnostic devices and methods, service technicians can properly troubleshoot business refrigeration systems and give specific and fast repairs, lessening downtime and guaranteeing optimal system efficiency.

Quick Repairs for Refrigeration Issues

When faced with refrigeration problems, technicians can implement fast repairs to deal with common concerns quickly and effectively. If the refrigeration system is not cooling properly, examining and adjusting the thermostat setups might offer a fast remedy prior to even more in-depth troubleshooting is required. By applying these quick fixes, service technicians can resolve common refrigeration problems efficiently and keep commercial refrigeration systems running smoothly.

Preventative Upkeep Tips

Carrying out a proactive upkeep routine is critical for guaranteeing the durability and optimal efficiency of industrial refrigeration systems. Regular upkeep not only aids stop expensive breakdowns however also makes certain that the tools operates effectively, saving energy and lowering general operating costs. Below are some preventative maintenance ideas to keep industrial refrigeration systems running efficiently:

Check and Change Filters: Dirty filters can restrict air flow, making the system work tougher and potentially triggering damage. Examine and replace filters consistently to avoid concerns.

Inspect Seals and Gaskets: Leaking seals page and gaskets can bring about temperature variations and power waste. Inspecting and changing harmed seals can help preserve regular temperatures.

Expert Support and Provider

To preserve the optimum performance attained with regular preventative upkeep, looking for expert support and solutions for commercial refrigeration systems is important. Expert professionals have the knowledge and specialized knowledge required to identify and deal with complicated concerns effectively. When facing difficult refrigeration issues, relying upon expert support can conserve both time and money in the lengthy run.

Expert services supply advantages such as accessibility to innovative devices and tools, guaranteeing that repairs are performed browse around these guys properly. In addition, service technicians are educated to adhere to industry regulations and security criteria, decreasing the danger of accidents and guaranteeing conformity with lawful requirements.

Verdict

Finally, fixing business refrigeration repair work requires an organized approach to determining typical concerns, using analysis devices and strategies, applying fast repairs, and focusing on preventative upkeep. Specialist support and services might be needed for more facility problems - commercial refrigeration repair. By adhering to these redirected here methods, companies can guarantee their refrigeration systems run efficiently and successfully, minimizing downtime and prospective losses

Understanding the common concerns that afflict industrial refrigeration systems and having a toolkit of analysis methods at your disposal can make all the distinction in promptly identifying and treating troubles.Efficient troubleshooting of business refrigeration systems depends greatly on using specialized analysis tools and methods to determine and deal with underlying concerns efficiently. By combining these diagnostic devices and strategies, technicians can successfully repair business refrigeration systems and provide accurate and quick repair services, minimizing downtime and ensuring ideal system efficiency.

By applying these fast repairs, specialists can address typical refrigeration issues successfully and maintain commercial refrigeration systems running smoothly.

In addition, specialist assistance can assist prolong the life-span of commercial refrigeration systems by recognizing prospective concerns before they rise.

Report this page